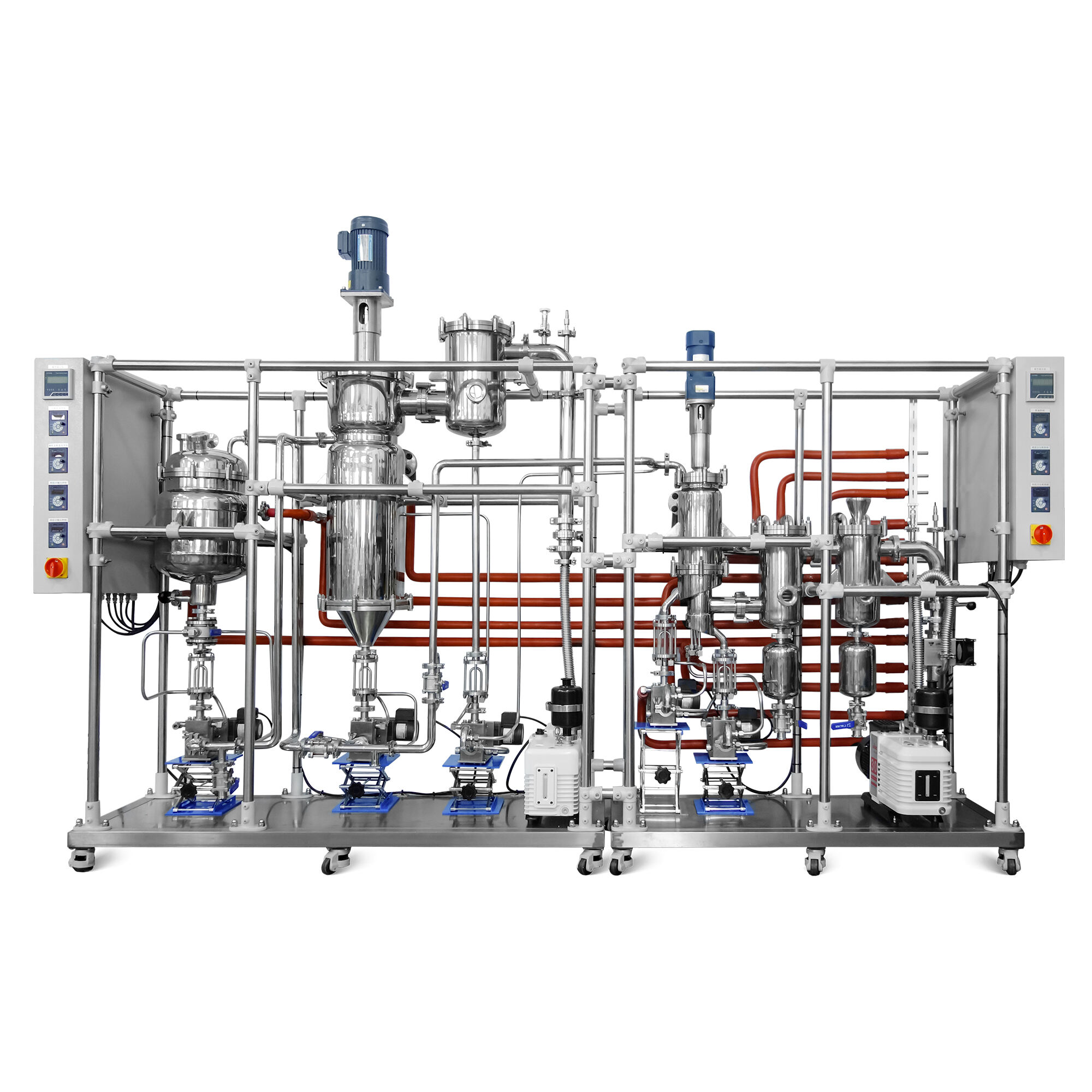

wiped film molecular distillation

Wiped film molecular distillation represents a sophisticated separation technology that operates under high vacuum conditions to efficiently separate heat-sensitive compounds. This advanced process utilizes a mechanically wiped, thin-film evaporator system where the feed material is distributed as a thin film across a heated surface. The distinctive feature of this technology lies in its ability to perform separations at molecular level, operating at extremely low pressures and relatively low temperatures. The process involves the continuous formation of a thin film of liquid that's spread across the evaporator wall by rotating wipers, ensuring maximum heat transfer efficiency and minimal residence time. The molecular distillation process is particularly valuable for processing thermally sensitive materials, as it prevents thermal degradation while achieving high-purity separation. This technology finds extensive applications across various industries, including pharmaceutical manufacturing, food processing, cosmetics production, and specialty chemical refinement. The system's capability to handle high-viscosity materials and its precise control over processing parameters makes it an invaluable tool for producing high-quality distillates and concentrates. The technology excels in separating compounds with different molecular weights and boiling points, making it essential for purification processes that require exceptional precision and product quality.