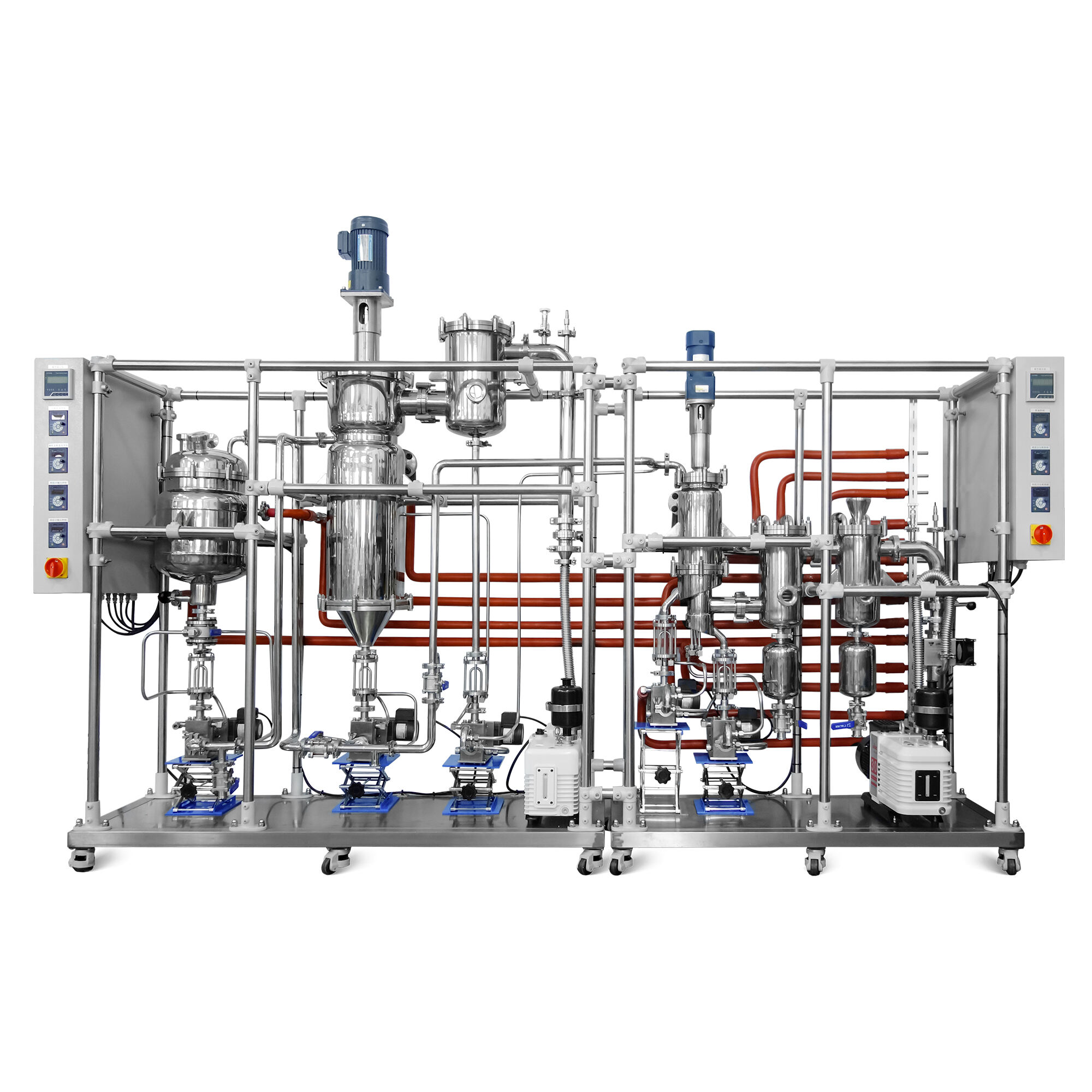

molecular distillation system

The molecular distillation system represents a cutting-edge separation technology that operates under high vacuum conditions to achieve precise molecular separation. This advanced process functions at significantly lower temperatures compared to conventional distillation methods, making it ideal for heat-sensitive materials. The system utilizes the difference in mean free paths between molecules to achieve separation, with lighter molecules evaporating and being collected on the condensing surface while heavier molecules remain as residue. Operating at pressures below 0.001 mbar, this technology ensures minimal thermal degradation of processed materials. The system comprises several key components, including a feeding system, evaporator, condenser, and collection vessels, all working in harmony to achieve optimal separation results. Its sophisticated design allows for continuous operation, enabling efficient processing of various materials including pharmaceuticals, cosmetics, and nutritional supplements. The technology excels in separating compounds with similar boiling points but different molecular weights, achieving exceptionally high purity levels often exceeding 99%. Modern molecular distillation systems incorporate advanced control systems for precise temperature regulation and pressure management, ensuring consistent and reliable performance. This versatile technology finds extensive applications in industries requiring high-purity compounds, particularly in the processing of heat-sensitive materials such as vitamins, omega-3 fatty acids, and specialty chemicals.