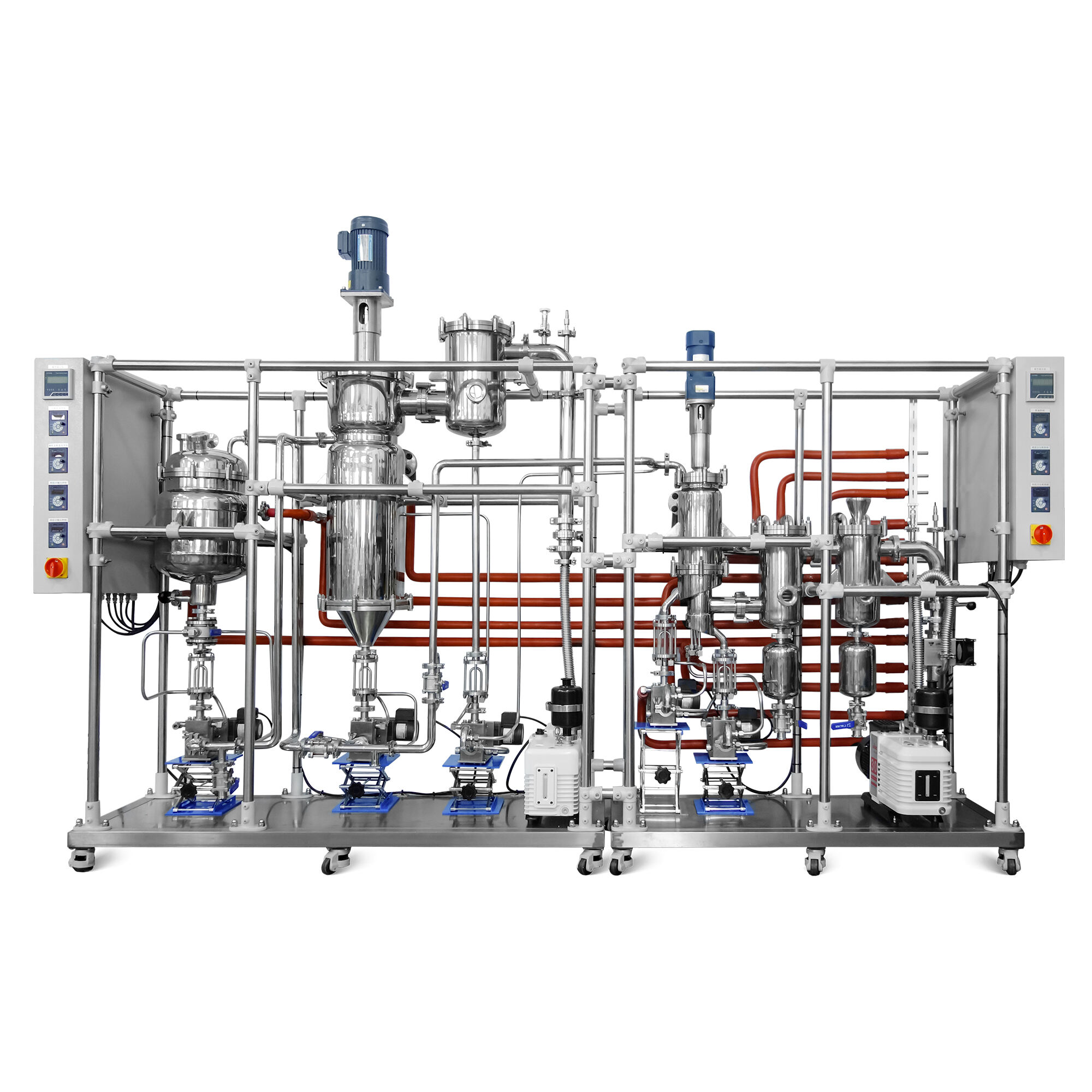

double molecular distillation

Double molecular distillation represents a sophisticated separation technology that operates under high vacuum conditions to purify heat-sensitive materials. This advanced process involves two consecutive distillation stages, each operating at specific temperatures and pressures to achieve optimal separation. During the process, molecules travel a very short distance between the evaporator and condenser surfaces, typically only a few centimeters, which significantly reduces the risk of thermal degradation. The first distillation stage removes volatile impurities and lighter fractions, while the second stage concentrates the desired compounds and eliminates heavier contaminants. This technique is particularly valuable for processing temperature-sensitive materials such as vitamins, fish oils, and specialty chemicals. The system maintains precise temperature control throughout both stages, ensuring consistent product quality and maximum yield. Modern double molecular distillation units are equipped with automated controls, allowing for continuous operation and real-time monitoring of crucial parameters. The technology's ability to operate at lower temperatures compared to conventional distillation makes it ideal for preserving the integrity of thermally unstable compounds.