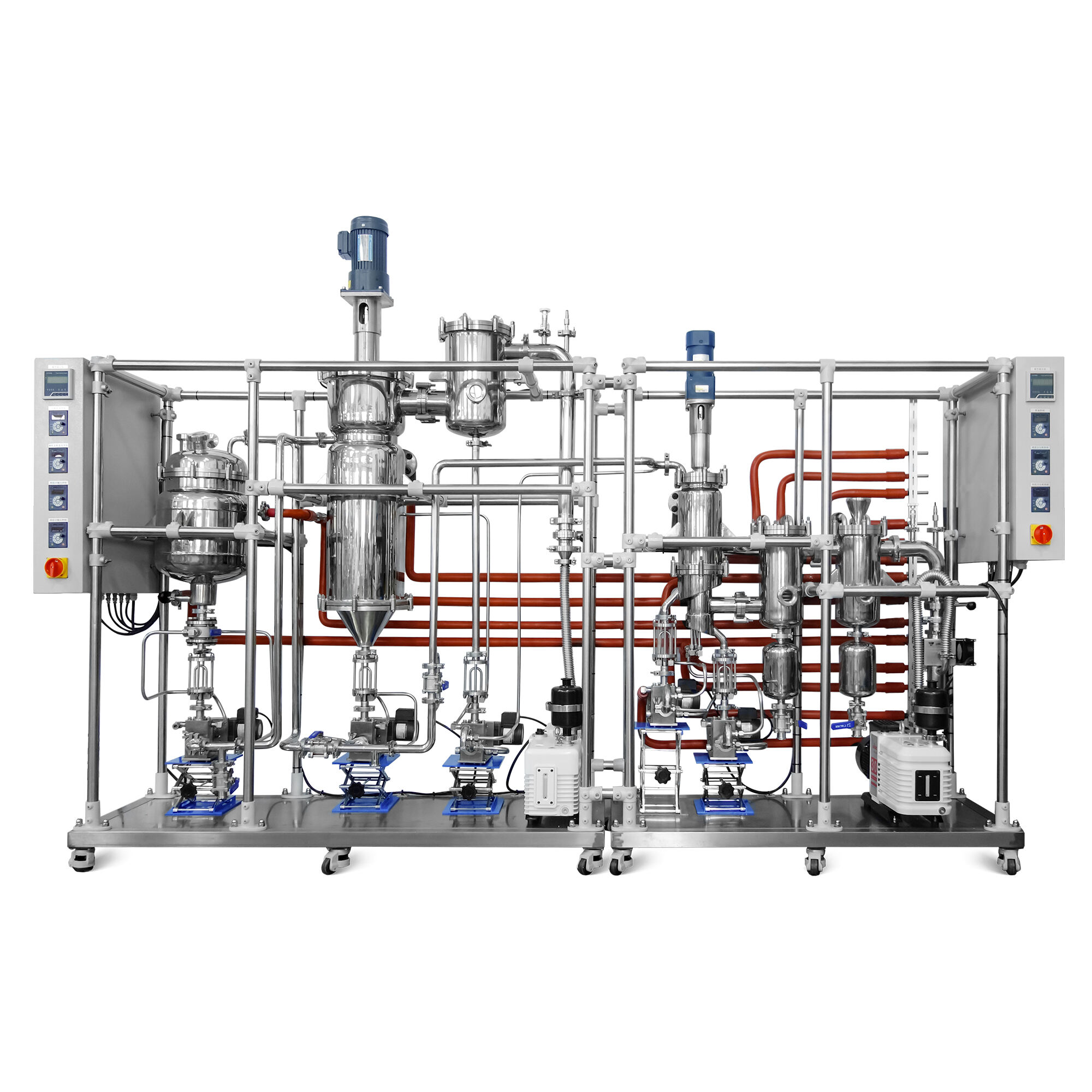

short path molecular distillation

Short path molecular distillation is an advanced separation technology that operates under high vacuum conditions to effectively separate and purify heat-sensitive compounds. This sophisticated process works by creating an extremely short distance between the evaporator and the condenser, typically ranging from 2 to 10 centimeters, which allows molecules to travel a minimal distance before condensing. The technology functions at very low pressures, usually between 0.001 to 0.01 mbar, enabling separation at temperatures significantly lower than conventional distillation methods. The process involves the material being spread into a thin film on the evaporator surface, where volatile components are rapidly vaporized and then immediately condensed on the nearby condenser surface. This method is particularly valuable for processing thermally sensitive materials, as it minimizes the exposure time to elevated temperatures and prevents thermal degradation. The technology finds extensive applications in various industries, including pharmaceutical, cosmetic, food, and chemical processing, where it's used for purifying vitamins, concentrating omega-3 fatty acids, and producing high-purity specialty chemicals. Its ability to handle complex mixtures while maintaining product integrity makes it an indispensable tool in modern industrial processes.