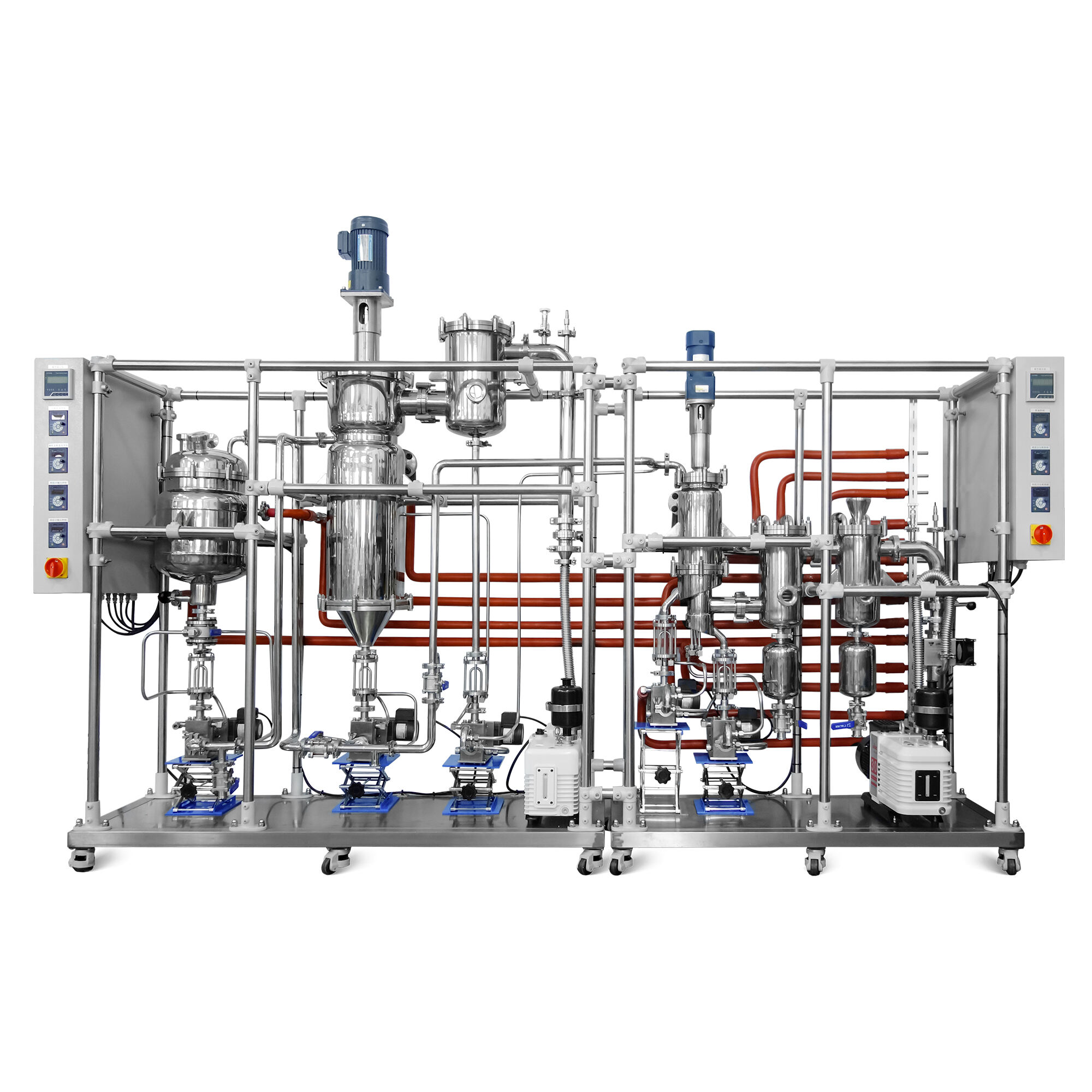

molecular distillation equipment

Molecular distillation equipment represents a sophisticated separation technology that operates under high vacuum conditions and low temperatures. This advanced system efficiently separates heat-sensitive compounds based on their molecular weights and vapor pressures, making it invaluable for processing temperature-sensitive materials. The equipment consists of several key components, including a feeding system, distillation chamber, heating system, condensing unit, and vacuum system. Operating at pressures below 0.01 mbar, the equipment creates extremely short exposure times to elevated temperatures, typically ranging from 0.1 to 2 seconds. This unique feature enables the separation of compounds with minimal thermal degradation, preserving their essential properties. The technology excels in processing various materials such as oils, vitamins, pharmaceuticals, and cosmetic ingredients. The process involves creating a thin film of material on the evaporator surface, where molecules with lower boiling points evaporate and are subsequently condensed on a separate surface. This method ensures high-purity separation while maintaining product integrity, making it particularly valuable for industries requiring precise molecular separation and purification processes.