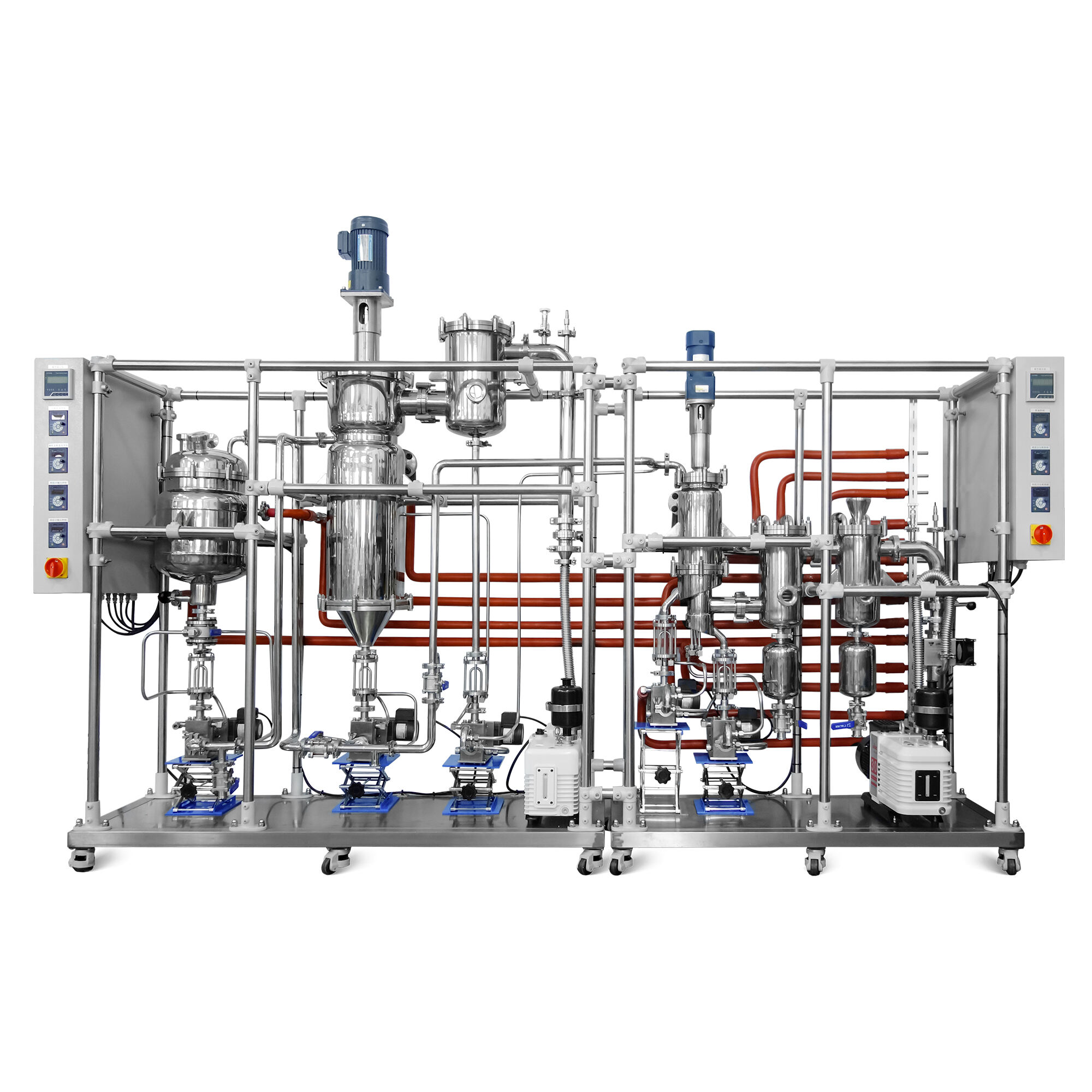

molecular distillation unit

A molecular distillation unit represents a sophisticated separation technology that operates under high vacuum conditions to separate and purify heat-sensitive compounds. This advanced system functions by creating an extremely short path between the evaporator and condenser surfaces, typically just a few centimeters, allowing molecules to transfer without intermolecular collisions. The unit operates at pressures below 0.01 mbar and temperatures significantly lower than conventional distillation methods, making it ideal for processing thermally sensitive materials. The system consists of several key components, including a feed system, heating element, evaporator surface, condenser, vacuum system, and collection vessels. The process begins when the feed material is spread in a thin film across the heated evaporator surface. Volatile components quickly evaporate and travel the short distance to the cooled condenser surface, where they immediately condense and are collected. This efficient separation occurs at the molecular level, hence the name molecular distillation. The technology finds extensive applications in various industries, including pharmaceutical processing, food oil refining, cosmetics manufacturing, and the production of vitamins and nutritional supplements. Its ability to separate compounds with similar boiling points and process heat-sensitive materials without degradation makes it an invaluable tool in modern industrial processes.