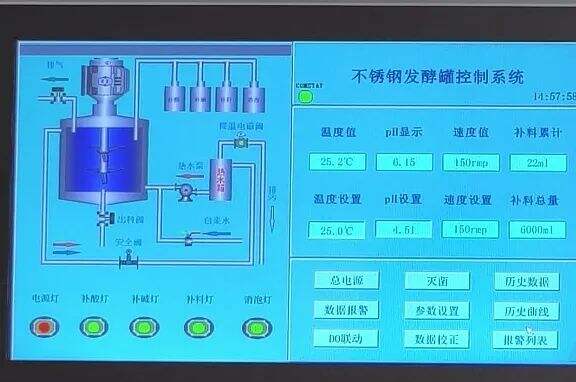

Laboratory fermenter consists of tank, agitation system, aeration system, temperature control system, pH control system, defoaming system, and monitoring and control devices.

Product Details

-

Fermenter tank mouth: contains a number of interfaces, used to connect the ventilation, feeding, discharging and other pipelines, is the key part of the fermentation process to realize the transmission of substances.

-

Stirring system: the stirring device can make the fermentation liquid mix evenly, promote the microorganisms and nutrients to fully contact, to ensure the stability and uniformity of the fermentation process.

-

Control system valves: valves belong to the control system, through these valves can accurately control the gas, liquid, etc. in and out, is the control hub of aeration, feeding and other links.

-

Ventilation or replenishment device: used for ventilation or replenishment during the fermentation process, the blue bottle cap container can store gas or liquid nutrients, connected to the fermenter through the pipeline, replenishing substances for the fermentation system as needed.

-

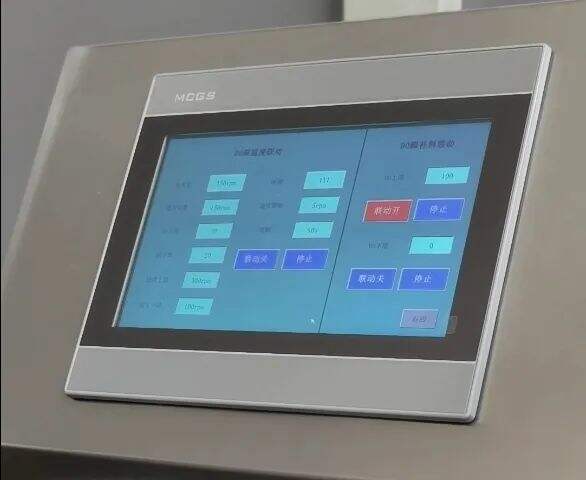

PLC control system on the right side: real-time monitoring and adjustment of the operating parameters of the fermenter, such as temperature, pH value, stirring speed, ventilation, etc., to achieve precise control of the fermentation process.

-

Piping interface and control valves on the left side of the fermenter: Containing multiple piping interfaces for connecting different functional piping, such as feed pipe, discharge pipe, ventilation pipe, etc.; control valves of different colors can control the circulation and flow of different media to ensure the orderly transmission of the fermentation process.

Areas of application

-

Food industry: used in the production of dairy products such as yogurt and lactic acid bacteria drinks; brewing beer, wine and other liquors; making fermented bread; producing soy sauce, sauce and other condiments.

-

Pharmaceutical industry: used in the production of antibiotics, the production of vaccines, the synthesis of biological drugs, such as monoclonal antibodies and recombinant proteins, as well as the biosynthesis of related enzymes.

-

Bioengineering: utilizing genetic engineering technology to introduce target genes into microorganisms or cells for large-scale cultivation through fermentation tanks to produce desired biological products.

-

Fine chemical industry: e.g. production of organic acids, amino acids and other chemical raw materials.

-

Energy field: Convert biomass such as crop straw and wood into renewable energy through bio-fermentation, e.g. bio-ethanol, bio-diesel, etc.; it can also be used for the production of bio-gas, e.g. methane.

Hot News

Hot News