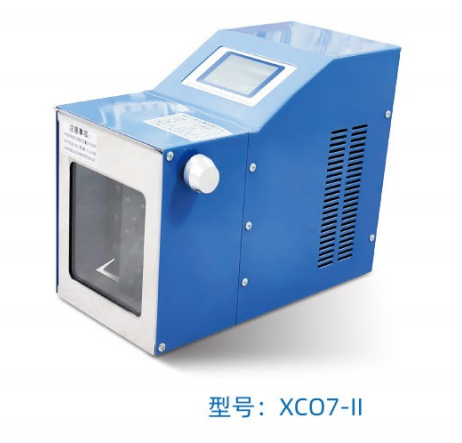

laboratory homogenizer

A laboratory homogenizer is a sophisticated piece of equipment designed to create uniform and stable mixtures from various substances. This versatile instrument operates by applying high pressure and mechanical forces to break down particles, cells, or droplets into smaller, consistently sized components. The device typically consists of a high-pressure pump system, a homogenizing valve, and precise control mechanisms that ensure reliable and reproducible results. Modern laboratory homogenizers can process samples ranging from a few milliliters to several liters, making them suitable for both research and small-scale production applications. The homogenization process involves forcing the sample through a precisely engineered gap under high pressure, creating intense shear forces that effectively reduce particle size and achieve thorough mixing. These machines are capable of handling various materials, including emulsions, suspensions, and cell cultures, with processing pressures typically ranging from 500 to 30,000 psi. Advanced models feature digital controls, temperature monitoring systems, and adjustable pressure settings, allowing users to optimize conditions for specific applications. The technology finds extensive use in pharmaceutical research, biotechnology, food science, and cosmetic development, where consistent particle size and uniform distribution are crucial for product quality and research accuracy.