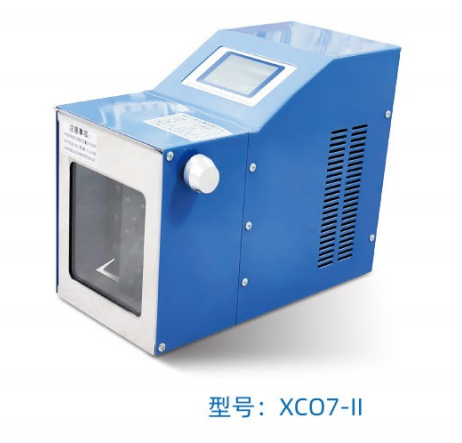

cell homogenizer

A cell homogenizer is a sophisticated laboratory instrument designed to efficiently break down cellular structures and extract cellular components through mechanical forces. This essential piece of equipment operates by subjecting cellular samples to intense pressure, shear forces, and cavitation, effectively disrupting cell membranes while preserving the integrity of intracellular components. The device employs various mechanisms, including high-pressure systems, rotating blades, or ultrasonic waves, to achieve consistent and reproducible cell disruption. Modern cell homogenizers feature precise control systems that allow researchers to adjust parameters such as pressure, speed, and processing time according to specific sample requirements. These instruments are equipped with advanced safety features and often include temperature control mechanisms to prevent sample degradation during processing. The versatility of cell homogenizers makes them indispensable in numerous applications, from pharmaceutical research and biotechnology to food processing and cosmetics manufacturing. They excel in preparing samples for protein extraction, DNA isolation, vaccine development, and the production of cell lysates for various analytical procedures.