دورانيات التبريد ذات درجة الحرارة المنخفضة

إن مُعَدِّي التبريد الدائري منخفض الحرارة من شركة نينكاي إنسترومينتس، من خلال تدوير زيت التبريد الاصطناعي أو الكحول الصناعي أو خليط الماء والجليكول، يوفّر بيئة منخفضة الحرارة لعمليات الإنتاج الصناعي الثقيلة في مجالات الكيميائيات والطاقة والغذاء والأدوية وهندسة الأحياء والفلزات وغيرها، ويضمن توفير ظروف منخفضة الحرارة بشكل مستقر، كما يمتلك أيضًا وظائف متعددة الحماية الأمنية الشاملة ومراقبة درجة حرارة البيئة وغيرها من الوظائف، لضمان التشغيل الموثوق وتمديد عمر الوسائط الساخنة والباردة لتحقيق التشغيل المستمر على مدار 24 ساعة!

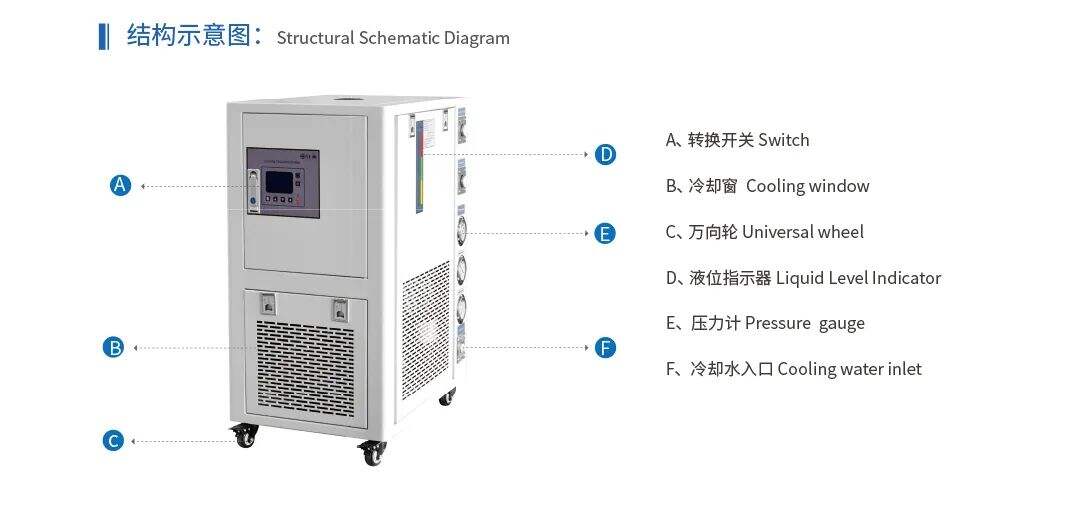

مُعَدِّو التبريد الدائري منخفض الحرارة من شركة نينكاي إنسترومينتس متوفران ب вариант воздي (تبريد بالهواء) و вариант مائي (تبريد بالماء).

مُعَدِّو التبريد الدائري منخفض الحرارة بتبريد بالهواء

اجبر تدفق الهواء عبر المروحة، باستخدام الهواء كوسيلة تبريد لتوزيع الحرارة الناتجة عن نظام التبريد على البيئة المحيطة. لا حاجة لتوصيل خطوط المياه للتبريد، قم بتوصيلها واستخدامها فورًا، تطبيق مرن، مناسب للمختبرات والمعدات الصغيرة وأي أماكن متحركة وقابلة للنقل.

مُبرِّد دوّار تبريد بالماء

يتم دفع تدفق ماء التبريد بواسطة مضخة ماء لنقل الحرارة الناتجة عن نظام التبريد إلى ماء التبريد، ومن ثم يتم طرد هذه الحرارة إلى الخارج من خلال برج التبريد أو وحدة تبريد المياه. يتطلب وجود نظام مائي للتبريد، استقرار عالي، ومناسب للمعدات الكبيرة الخاصة بالبحث العلمي وغيرها من الحالات.

تغطي المبردات الدوّارة ذات التبريد الم cryogenic نطاقًا واسعًا من درجات الحرارة، مع مدرجات مختلفة مثل: -20℃~30℃، -40℃~30℃، -65℃~-20℃، -80℃~-20℃، -80℃~-130℃، إلخ.

في عملية تجفيف الأدوية بالتجميد بدرجة الحرارة المنخفضة للغاية، تكون متطلبات العمق والاستقرار في درجة الحرارة منخفضة للغاية، ويمكن للنماذج ضمن نطاق -80℃~-20℃ أن تخلق بدقة بيئة شديدة البرودة لضمان الحفاظ على المكونات الفعالة في المنتجات الدوائية.

وفي إنتاج مكونات إلكترونية عالية الجودة، يمكن لنطاق درجات الحرارة -65℃~-20℃ أن يلبي متطلبات اختبار درجات الحرارة المنخفضة للمكونات الدقيقة.

أما في حلقة التجميد السريع في صناعة الأغذية، فيمكن اختيار المعدات المناسبة وفقاً لنطاق درجات الحرارة القياسية الفعلية للتجميد السريع، بحيث يكون إنتاج 'البرودة' مناسباً ودقيقاً، وتجنب تأثير سوء توافق درجات الحرارة على جودة المنتج وكفاءة الإنتاج.

تختلف قدرة التبريد بشكل كبير من نموذج إلى آخر، حيث تتراوح من 1.5 كيلوواط للمختبرات الصغيرة إلى 500 كيلوواط للاستخدام الصناعي.

|

|

مبرد مختبر صغير |

مبردات صناعية |

يمكن لمعدات ذات سعة تبريد صغيرة أن تلبي متطلبات الاختبار في مجال البحث والتطوير في الهندسة الحيوية الصغيرة. أما بالنسبة لخطوط الإنتاج металлورجي الكبيرة، فإن النماذج ذات السعة التبريدية العالية تضمن استمرارية الإنتاج في بيئة منخفضة الحرارة، ويجب اختيارها وفقًا لحجم الإنتاج لتجنب حالات "الحصان الكبير يجر عربة صغيرة" أو "ال pony pulling".

يمكن تخصيص مبردات التبريد عند درجات الحرارة المنخفضة لتكون مقاومة للانفجار.

إن معدل تدفق مضخة الدورة وحجم الخزان يؤثران أيضًا على الاستخدام. تكون المضخات الدوّارة ذات التدفق العالي مناسبة للمشاهد التي تتطلب تبادل حراري سريع؛ والخزانات الكبيرة يمكن أن تقلل من تكرار إعادة تعبئة السائل. بالإضافة إلى ذلك، فإن تكوين الضاغط والمكثف يؤثر أيضًا على استقرار المعدات وكفاءة نقل الحرارة.

اختيار مبردات التدوير ذات التبريد الم cryogenic، من درجة الحرارة والسعة التبريدية وحتى تفاصيل المعلمات، بحيث يتم التوافق بدقة، مما يسمح للإنتاج الصناعي بالعمل بكفاءة واستقرار في بيئة ذات درجة حرارة منخفضة، وضمان جودة المنتج وكفاءة الإنتاج ~!

إذا كنت لا تزال مشوشًا بشأن اختيار النموذج، وغير متأكد من أي من مبردات التدوير cryogenic هي الأنسب لاحتياجات الإنتاج، فيمكنك التواصل في أي وقت مع فريقنا المهني، حيث سنقوم بدمج ذلك مع سيناريوهاتك الفعلية لتزويدك بإرشادات دقيقة وشاملة للاختيار.

أخبار ساخنة

أخبار ساخنة2025-08-06

2025-07-30

2025-07-18

2025-07-07

2025-06-06

2025-05-15