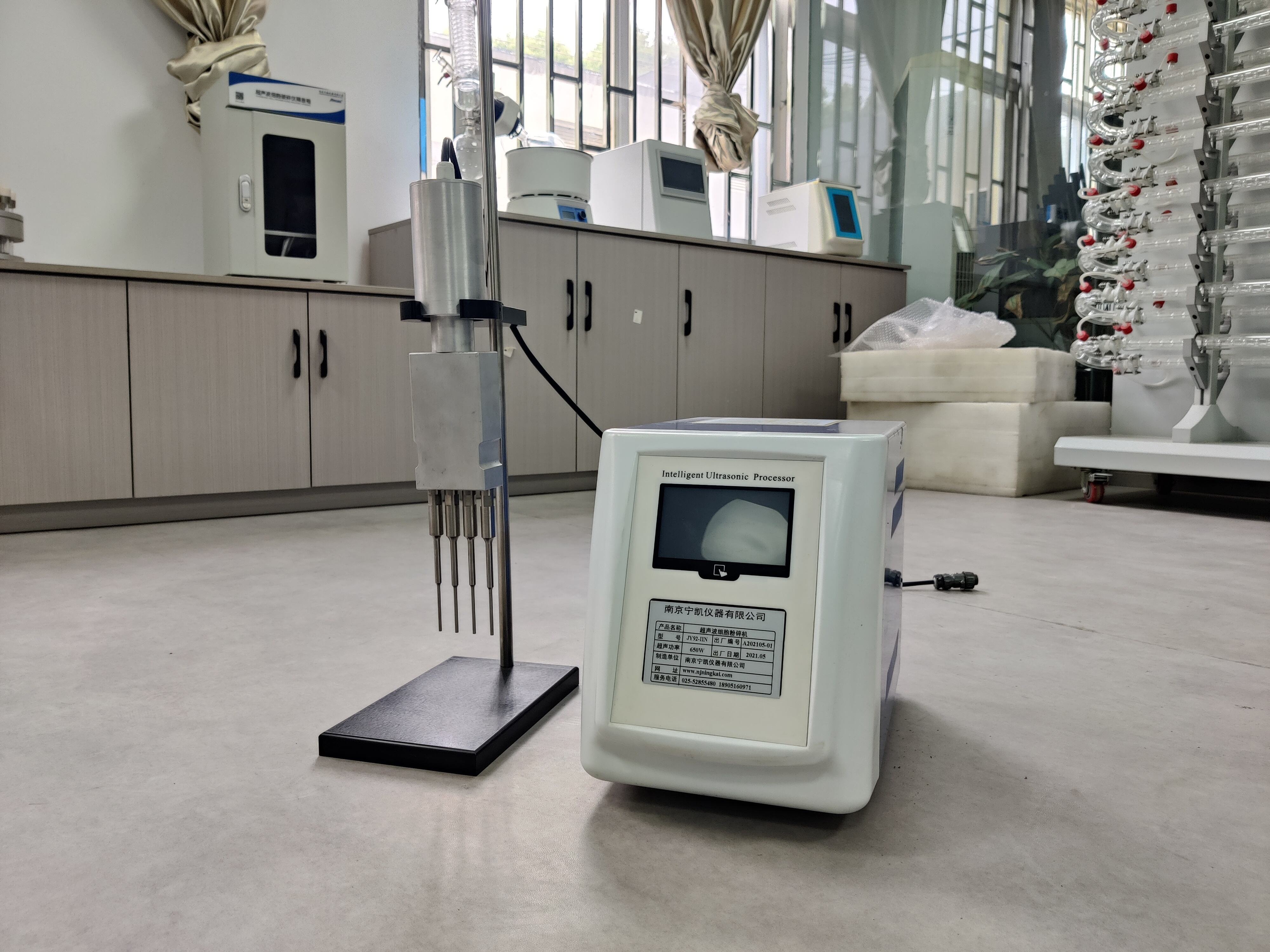

ultrasonic cell crusher made in china

The ultrasonic cell crusher made in China represents a cutting-edge solution for cellular disruption and sample preparation in laboratory settings. This sophisticated device utilizes high-frequency ultrasonic waves to effectively break down cellular structures, making it an invaluable tool for various scientific applications. The system operates by converting electrical energy into mechanical vibrations, creating powerful cavitation effects that disrupt cell membranes and release cellular contents. Operating at frequencies typically ranging from 20kHz to 40kHz, these machines offer precise control over the sonication process, allowing researchers to achieve optimal results for different sample types. The device features advanced temperature control mechanisms to prevent sample degradation during processing, while its digital interface enables precise adjustment of parameters such as amplitude, pulse duration, and processing time. The construction typically incorporates high-grade stainless steel components, ensuring durability and resistance to chemical corrosion. These cell crushers are designed to handle various sample volumes, from microliters to larger quantities, making them versatile for different research needs. The equipment comes with interchangeable probes of different diameters to accommodate various sample sizes and vessels, enhancing its adaptability across different applications.