Customizable Precision Control Panel for Glass Bioreactor - ±0.1℃ PID with PH/DO/Agitation Sync for Microbial Culture

Product Category

Tag

- Description

-

Product Description

The cell culture system of 1L-5L bioreactor is composed of 3-6units of 1L bioreactors that are able to operate independently. lt ismainly used in small scale,continuous or discontinuousmicroorganism or cell culture to compare parameters of multi-processes in the phase of bioprocess exploitation and processoptimizing. Relative to shake-flask culture, it is able to test onlineand control process parameters,such as temperature, pH,dissolved oxygen,aeration and agitation speed. Also thebioreactor has sampling devices that are safe and convenientwhich is able to analyze and compare data outside. The monitoringsystem is able to record and observe the 1L-5L bio-reactor andadjust parameters during the process of culture.

Product Paramenters

Details Images

Kettle Lid

Kettle Lid

LCD/PLC Touch screen Interface accurate monitoring of PH valueNumber of openings available

1. Air inlet

2. DO electrode hole

3. Cooling water inlet

4. sampling tube

5.Temperature sensor

6. Air outlet

7. Defoaming electrode

8. Cooling water outlet

9. PH electrode hole

10. Air inlet

11. Defoaming port

12. Feeding inlet

13. Alkali port

14. Acid port

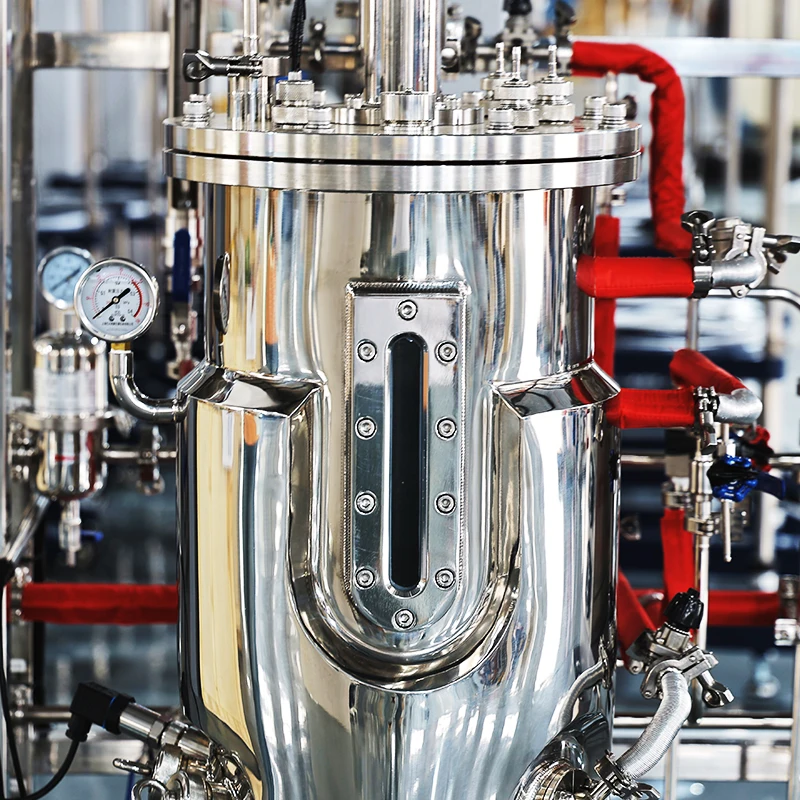

Kettle Body

Fermenter kettle body is the core fermentation components, mainly composed of cylinder and head, the cylinder is mostlycylindrical, head common oval, disk-shaped and flat head. Material, food, pharmaceutical industry commonly used 304, 316L stainless steel; laboratory small fermenter with borosilicate glass; enamel material is used in the high demand forcorrosion-resistant scenes.

Stirring System

The stirring system of the fermentation tank mixes materials and transfers mass and heat via the rotation of the stirring paddle.Common types are axial flow paddles (like propeller and screw types) for up-down circulation and dissolved oxygen transfer, and radial flow paddles (such as turbine type) generating strong shear force for solid suspension and dispersion. The stirring speed should be precisely controlled based on the fermentation process and microbial characteristics. Too high speed may harm bacteria, and too low speed affects mixing and dissolved oxygen supply.

Company Profile

Packing & Delivery

1.Packing method: Standard export wooden box or base on your requests.

2. Shipping method: By Express door to door, or by ship, based on your choice.

1) If delivery goods by Express, door to door service , generally about 5-7 working days reach.

2) If by air, deliver goods to your destination airport, about 5 working days reach.

3) If by sea, deliver goods to your local seaport, specific days and cost is based on different shipping line.

3. Warranty: Any broken or damages of equipment caused by delivery, will be afforded by Nanjing Ningkai company.

4.Our expectations: Every item in the process of transportation carries our sincere intentions. We deeply understand that logistics serves as a crucial link connecting you with the products you desire. Whether you are in a remote area or a bustling city, and whether facing adverse weather conditions or complex customs formalities, we will spare no effort to overcome difficulties, deliver the goods promptly, and bring you a convenient and worry-free shopping experience.Shipping: By sea or by air as you wishes .( TNT , UPS , FedEx , EMS , DHL , SF or other logistics )FAQ

1.How long is the customization lead - time?

The delivery time is determined according to the complexity of the process. Under the condition of a simple process, delivery is generally made within two weeks.

2.How much is the customized price?

Our customized prices are mainly determined by the cost of raw materials, the complexity of the production process, and the uniqueness of your customization requirements. Since we are a factory at the source, we're open to price negotiations.

3.Do you have any certification certificates?

We have obtained the CE certification.

4.Will you provide operation training after purchase? And what are the training methods?

We offer user manuals and installation videos. Moreover, we can also provide on-site installation and testing services.

5.What's the warranty period of the equipment?

We offer a one-year free warranty.

6.What safety protection devices does the equipment have and what dangerous situations can they prevent?

Multiple safety protections are in place: automatic protection against over - temperature and over - pressure to prevent thermal run away and bursting; timely alarm and shutdown in case of leakage detection; an emergency stop button is provided; and there is also an explosion - proof device to ensure safe operation.

Customizable Precision Control Panel for Glass Bioreactor - ±0.1℃ PID with PH/DO/Agitation Sync for Microbial Culture

Product Category

Tag

Product Inquiry

We will contact you within one working day. Please pay attention to your email.

Related Products