Stainless steel 316 molecular distillation still molecular distillation manufacturer

Product Category

Tag

- Description

-

Product Description

Short path molecular distillation is a new technique that address the problems that conventional distillation techniques cannot solve . It can achieve liquid to liquid separation at very low vacuum degree according to the mean free path difference of molecular motion under the temperature of much lower than the liquid boiling point . Mainly the use of wiped system forcing liquid film evaporation or distillation of a highly efficient evaporation, distillation equipment , deodorization , degassing reaction and supporting heating , cooling and other unit operations , can be widely used in food , fine chemicals , electronic materials , plastic engineering and polymer purification , etc . The system also can be used to recover organic solvents from industrial effluents , especially for high boiling point , heat-sensitive , easily oxidized material separation and purification .

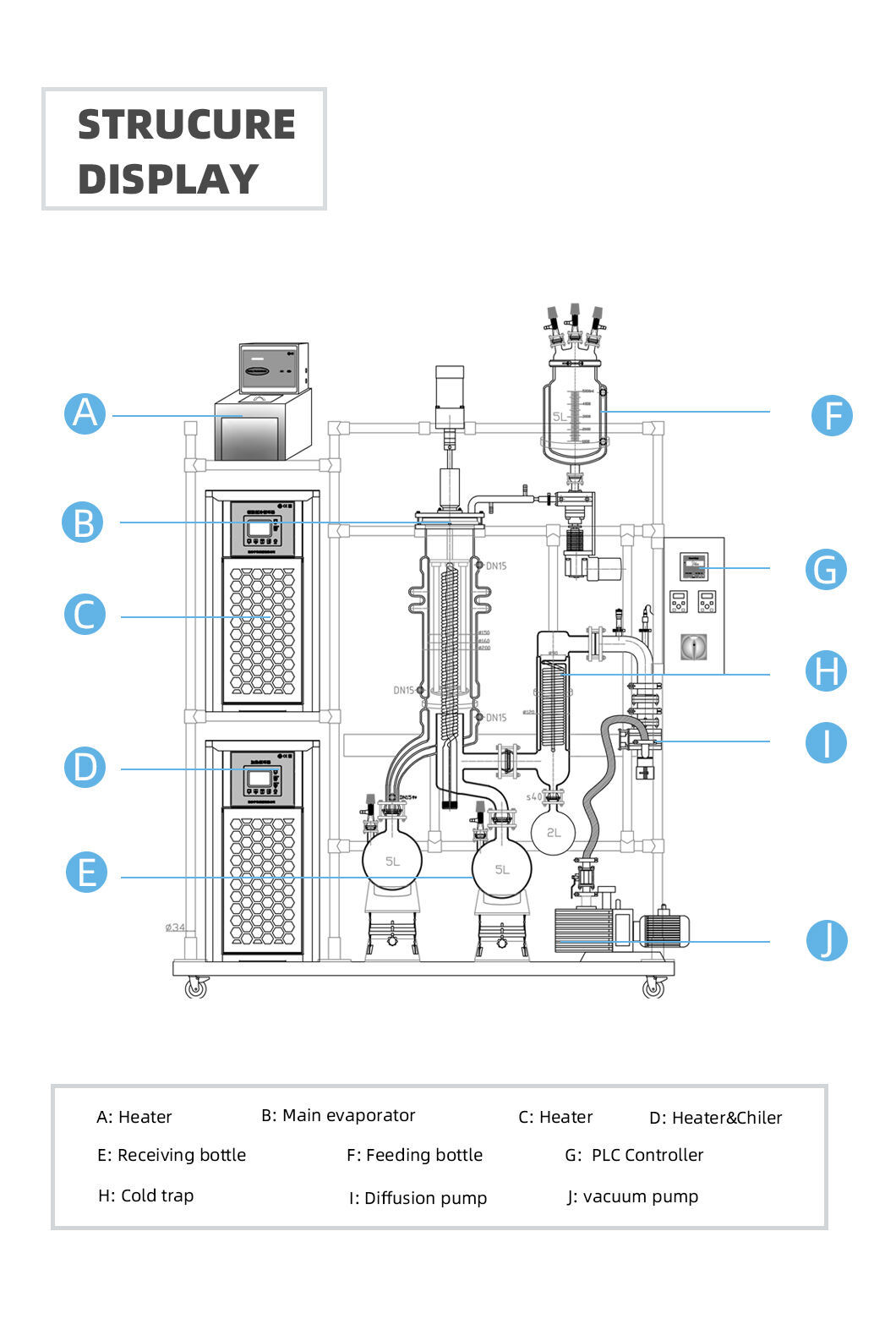

Working principle

1. Operating temperature is far below the boiling point of the material . It has a big advantage in handling the thermal material , bio-acid fat , high boiling point and the materials which is not easy to steam out .

2. Heating time is extremely short , ordinary distillation need to take few hours in the process, but our short path distillation only need few minutes .

3. Low carbon dioxide , environmentally friendly and good for maintaining the material activity.

4. Belong to the physical separation process , can keep the natural state of the material from pollution .

5. Widely used in high value-added materials deodorization , bleaching , purification and separation .

Product features

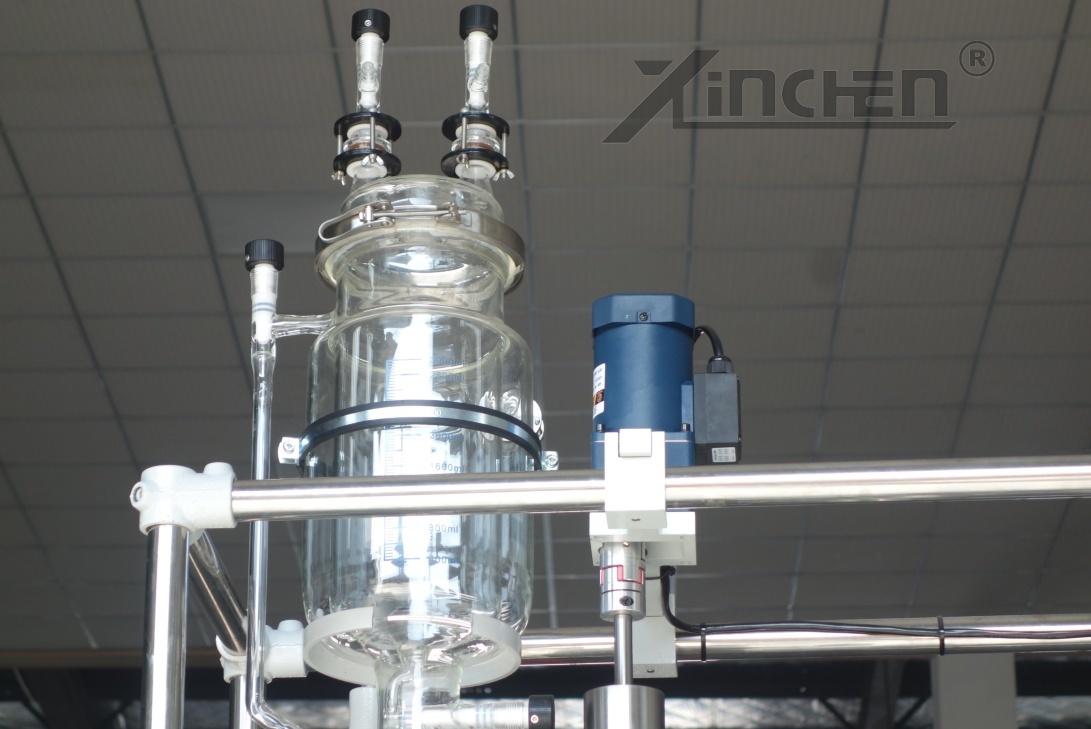

①Evaporation tube body using G3.3 borosilicate glass: easy to observe the material under different conditions of pressure, temperature, flow and speed changes (such as material color, viscosity, film-forming effect, out of the critical point, etc.).

Help to get the best process parameters and experimental data.

②Can achieve precise temperature control: the maximum temperature of the evaporation tube system can reach 200 ℃, the maximum temperature within the jacket up to 300 ℃;

③Transmission system: The magnetic coupling transmission, to ensure high-speed operation of the evaporation cylinder pressure limit system up to 0.001mbar

④Film self-cleaning roller or scraper system through the centrifugal force of the material into a film to improve the evaporation efficiency and reduce operating time;

⑤High cleanliness: the material in the separation process only contact with glass and PTFE composite material, no other pollution.

⑥Ease of maintenance: all flange design, easy disassembly.

⑦According to customer requirements, evaporation tube specifications Φ60 ∽ Φ300 optional.

Product Paramenters

Model evaporation tube specifications Φ (mm) Evaporation tube heat transfer area(㎡) Built-in cooling area (㎡) Constant pressure feeding bottle( L) Sample throughput (L/H) Motor power (W) motor speed (rpm) NKDF-60 60 0.05 0.03 1 0.8 140 800 NKDF-80 80 0.1 0.25 1 1.5 140 800 NKDF-100 100 0.15 0.3 1 3 180 800 NKDF-150 150 0.25 0.4 2 5 180 800 NKDF-200 200 0.4 0.5 3 8 250 800 NKDF-300 300 0.6 0.8 5 10 250 500 Detailed Images

Company Introduction

Ningkai Instrument Co . Ltd is located in Nanjing , China , where own hundreds of universities and research institutes. And famous as its thousands of years long history culture. Profound culture and strong scientific research strength , provide sustainable and vigorous power for Ningkai development .

Main products include Glass Reactor(single layer, double- layer and three- layer) , Rotary Evaporator , Short Path Molecular Distillation , Heating Circulators , Heating Refrigeration Circulator , Low Temperature Circulator , Ultrasonic Cell Crusher , Industrial Ultrasonic Treatment Equipment , Ultrasonic Cleaning Machine , High(Low) Temperature Constant Temperature Trough , Hybridization Oven , UV Cross-linker , Flap Type Homogenizer , Dry Bath and etc .

Ningkai Instrument has exported its products to Europe , South America , North America , Latin America , Asia , Australia , Middle East , Africa and etc . Providing technical support for tens of thousands organizations to solve problems within their research , special for university , research institutes, inspection agencies , industries and etc .

Our Services & Strength

1. Offer a complete service system from the start of the order to the end of the order.2. We are truly factory , located in

Nanjing City , China , specific address is No 7 Qingxing Road, Guli Industrial Park , Jiangning District , Nanjing City , Jiangsu

Province , China . Company title(name): "Nanjing Ningkai Instrument Co.,Ltd " .

3. 100% timely delivery after payment paid , for chemical , pharmaceutical , biological , laboratory production, delivery for 7-15 days , for wholesaler , retailer , trade company , delivery for 15-28 days .

4. We offer the video technical support , directly talking with our technical engineers about your questions .

5. Shipping cost, we will offer the reasonable and desirable product shipping fees , no matter the air or sea , or maybe the

international express . By air: 5-7 days , By sea: 30 - 40 days .

6. We have our own glass factory, purely hand-made , can meet with our customers demands .

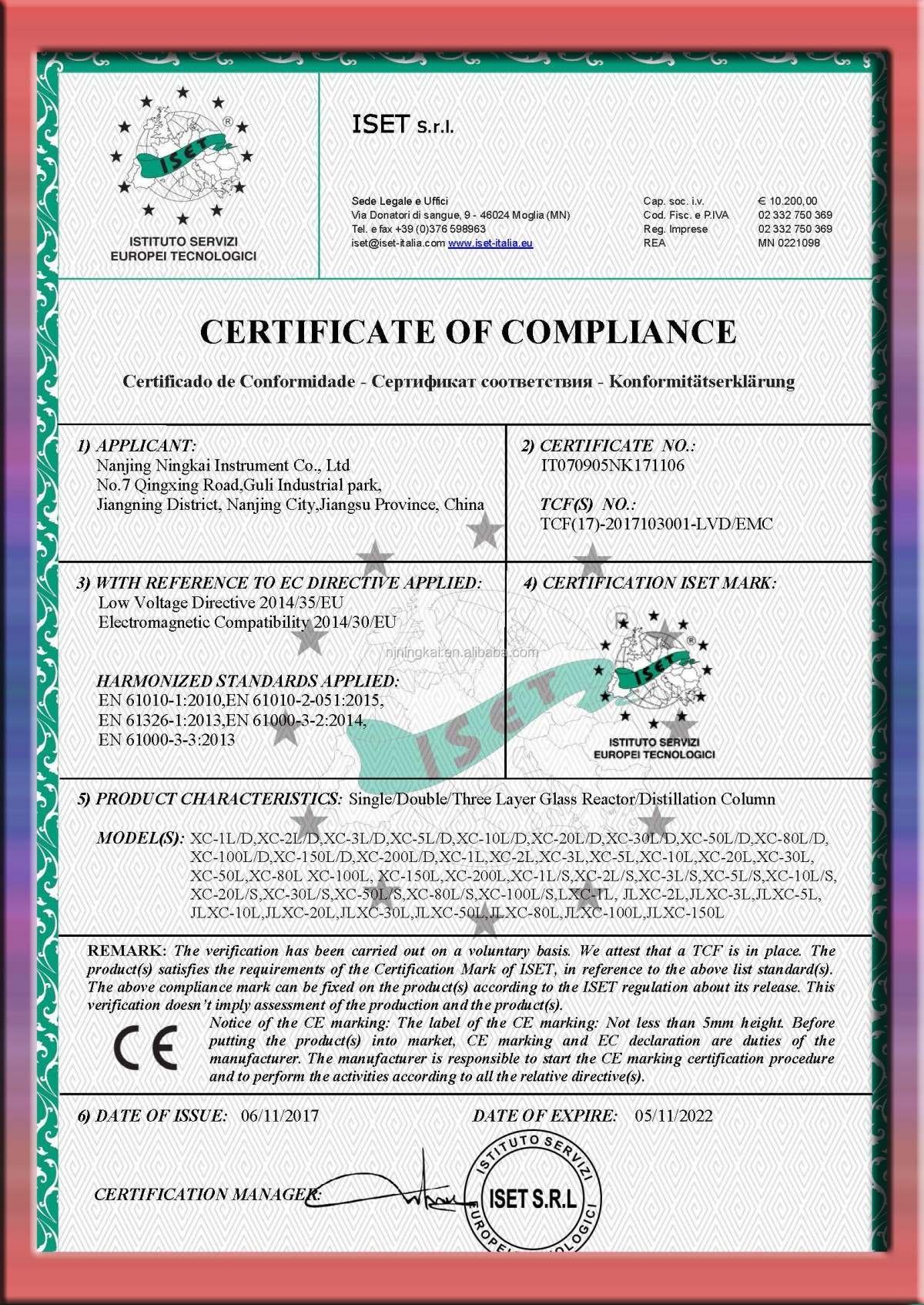

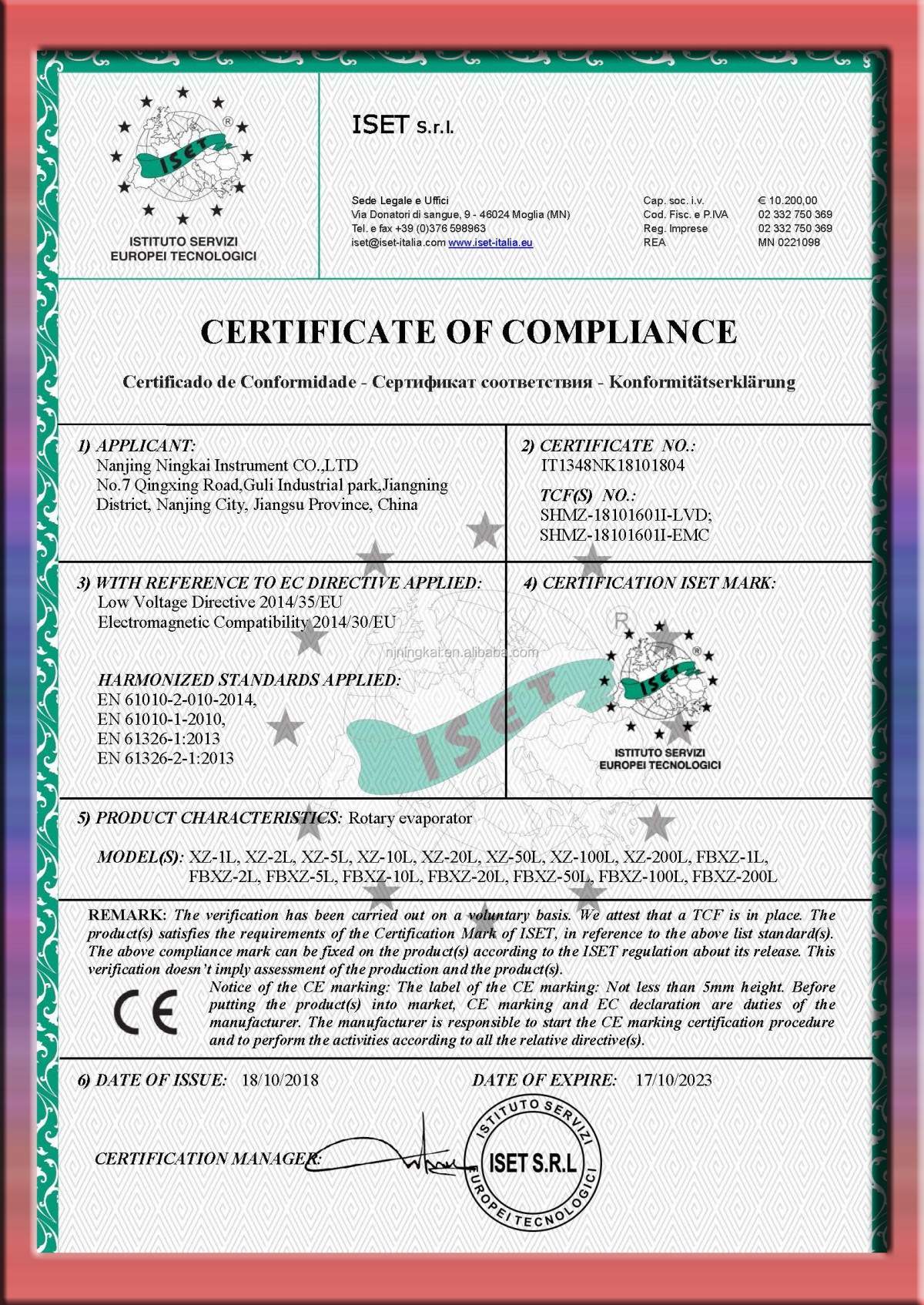

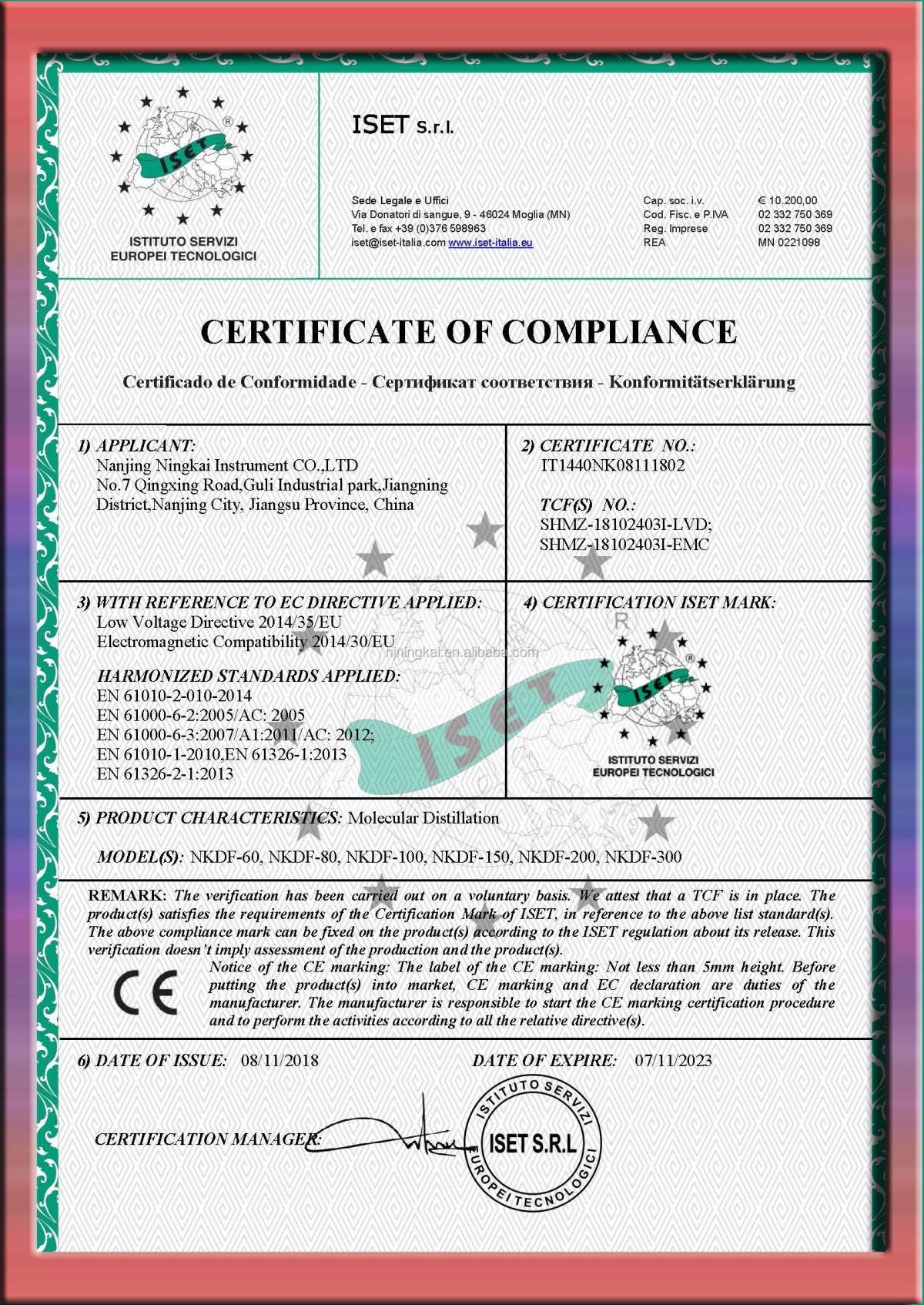

Certifications

FAQ

Q1. What is your terms of payment?

A: T/T 50% as deposit, and 50% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q2. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q3. How about your delivery time?

A: Generally, it will take 7 to 10 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q4. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We also can design for you.

Q5. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Stainless steel 316 molecular distillation still molecular distillation manufacturer

Product Category

Tag

Product Inquiry

We will contact you within one working day. Please pay attention to your email.

Related Products