20L Rotary Evaporator for Corrosive Chemicals Electric Powered Vacuum Distillation Process with Corrosion-Resistant Core Pump

Product Category

Tag

- Description

-

Products Description

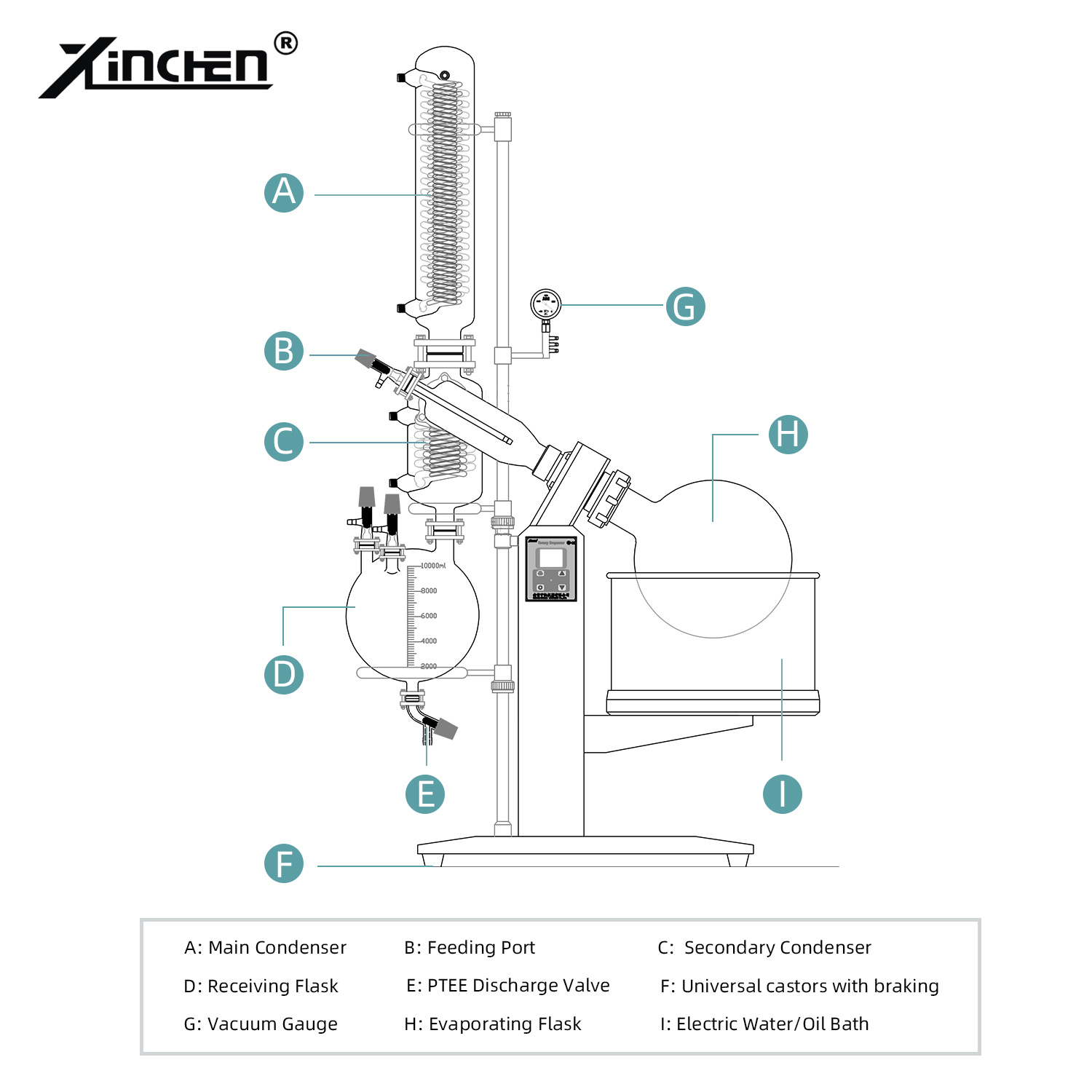

100L Rotary Evaporator is mainly used in the pilot-scale test and production in medicine, laboratory,solar energy, biological,

pharmaceutical, chemical,food and other fields.

As with large capacity and large-diameter rotary evaporating flask, when it is placed in a water bath,

along with the simultaneous performing of rotating and heating, it allows the solution spreading and evaporating rapidly.

The rotary evaporator is suitable for extracting solvent or separating mixed solution. It can be used in the following experiments

or product production:

☑Concentration of solutions;

☑Reclamation of solvents;

☑Separation of chemicals;

☑Vacuum drying of wet solids;

☑Essential oil extractor;

☑Remove solvent from sample.Details Images

Specifications

Optional Equipment.

Chiller/cooling circulator function:

1.With big cooling power.

2.Increase receiveing rate.

3.Save water resource.Vacuum pump:

1.Easy maintenance.

2.Resist certain corrosion.Company ProfileLathe and drilling machine machining

1.General lathe workers accurately control the depth of feedcleverly adjust the speed of speed, each cutting is smoothand robust, for the precision and quality of parts processing a key link.

2 Milling machine operators accurately adjust the spindlespeed, carefully calibrate the displacement of the table.each step of the operation is smooth and robust, so that theperformance of the drilling and milling machine to achievethe best, for the subseguent precision machining of the keystart.

Glass reactor assembly

Assembly workers concentrate on the assembly workers concentrate on the accordance with the process requirements, every action is skilledand stable, and the key to product quality

Electrical cabinet assembly

The electrical assembler is busy in front of the electrical cabinet, carefully wiring and debugging, so that every electrical component can accurately cooperateand inject "wisdom brain" into the equipment.

pipeline welding

Welders cut and polish the pipes, further welding... lt is theirmeticulous attention to detail, from the cold pipes to thetightly stitched fittings inside the equipment

Logistics support

The logistics staff who pay silently arethe "invisible guardians" of theworkshop. They carefully clean theworkshop, arrange materials, andcreate a comfortable working andproduction atmosphere, which is anindispensable force for the operation ofthe company.About Us

Packaging & Shipping

Standard export carton and wooden case with inner efficient protections( light but protective) . For the safety of the glass

components ( pipes , funnels, etc ) and accessories, some foam boards and bubble films will be put into carton package or thewooden package .

Neutral package and other packages with custom made are also available .

Please give us detailed requirements of your packages in advance .Exhibition and Certification

FAQ

FAQ1.How long is the customization lead - time?

The delivery time is determined according to the complexity of the process. Under the condition of a simple process, delivery is generally made within two weeks.

2.How much is the customized price?

Our customized prices are mainly determined by the cost of raw materials, the complexity of the production process, and the uniqueness of your customization requirements. Since we are a factory at the source, we're open to price negotiations.

3.Do you have any certification certificates?

We have obtained the CE certification.

4.Will you provide operation training after purchase? And what are the training methods?

We offer user manuals and installation videos. Moreover, we can also provide on-site installation and testing services.

5.What's the warranty period of the equipment?

We offer a one-year free warranty.

6.What safety protection devices does the equipment have and what dangerous situations can they prevent?

Multiple safety protections are in place: automatic protection against over - temperature and over - pressure to prevent thermal run away and bursting; timely alarm and shutdown in case of leakage detection; an emergency stop button is provided; and there is also an explosion - proof device to ensure safe operation.

20L Rotary Evaporator for Corrosive Chemicals Electric Powered Vacuum Distillation Process with Corrosion-Resistant Core Pump

Product Category

Tag

Product Inquiry

We will contact you within one working day. Please pay attention to your email.

Related Products